Woodworking Tools

Table Saw

Band Saw

- Wen 14″ band saw, model 3966

- Quick adjust blade tension

- Circle cutting jig

- 100 3/4″ blades, from 1/8″ to 1″ width

- ALWAYS use dust collection when running the band saw

- ALWAYS engage quick tension lever (lever in the back top center) before running band saw and release tension from band saw when done with it

- NEVER cut metal on this band saw. Besides not having the proper blade on it for cutting metal, the metal shavings can embed into other wood projects

Jointer

A jointer is a woodworking machine that is used to flatten and square the edges of boards and prepare them for gluing or joining. It consists of a flat, adjustable table and a rotating cutter head with knives that remove thin layers of wood from the board’s surface.

The jointer’s table is usually made of cast iron or steel and is mounted on a base that allows it to be adjusted to different angles and heights. The cutter head is typically driven by an electric motor and is housed in a metal guard for safety. The knives are adjustable and can be sharpened or replaced as needed.

To use a jointer, the board is placed on the table with one edge against the fence and the opposite edge facing up. The machine is turned on, and the board is pushed forward over the rotating cutter head, which removes a thin layer of wood from the board’s edge. This process is repeated until the board’s edge is flat and square.

In addition to squaring the edges of boards, a jointer can also be used to create chamfers or bevels on the edges and faces of boards. It can also be used to straighten and flatten warped or twisted boards.

Jointers are essential tools in woodworking shops, and they are commonly used by furniture makers, cabinet makers, and carpenters. With proper use and safety precautions, a jointer can help users achieve accurate and professional-quality results in their woodworking projects.

Combination Belt and Disc Sander

A disc and belt sander is a versatile power tool that combines a disc sander and a belt sander into one machine. The tool has a flat, circular sanding disc mounted on one side and a long, narrow belt sander on the other side. It is commonly used in woodworking and metalworking shops for sanding and shaping various materials.

The disc sander consists of a circular abrasive disc that spins at high speed. The sanding disc is usually made of abrasive paper or cloth and comes in various grits. The belt sander consists of a long, narrow abrasive belt that is driven by a motor and can be adjusted to different speeds and angles. The belt is typically made of abrasive cloth and can be replaced or changed to a different grit as needed.

To use a disc and belt sander, the material being sanded is held against the sanding disc or belt while the machine is turned on. The sanding disc is used for flat sanding and shaping, while the belt sander is used for sanding curved or irregular surfaces. The machine’s adjustable table can be used to support the material being sanded and can be tilted to different angles for bevel sanding.

Disc and belt sanders are commonly used in woodworking for sanding and shaping wood, as well as in metalworking for sanding and finishing metal parts. With the right sanding disc or belt, they can be used on a variety of materials, including plastics, composites, and even leather.

Safety precautions should be taken when using a disc and belt sander, including wearing eye and ear protection, using a dust collection system, and avoiding loose clothing or jewelry that can get caught in the machine. When used properly, a disc and belt sander can help users achieve smooth, even surfaces and precise shapes in their projects.

Spindle sander

A spindle sander is a woodworking machine that is used for sanding curved and irregularly shaped surfaces. It consists of a rotating spindle that protrudes through a flat table and is driven by an electric motor. The spindle has interchangeable sanding sleeves that can be changed to different diameters and grits as needed.

The table of a spindle sander is typically made of cast iron or steel and can be tilted to different angles for bevel sanding. The machine has various speed settings that can be adjusted to match the material being sanded and the size of the sanding sleeve.

To use a spindle sander, the material being sanded is held against the sanding sleeve while the spindle is rotating. The spindle’s oscillating motion allows the sanding sleeve to conform to the material’s contours and sand evenly across the surface. The machine’s adjustable table can be used to support the material being sanded and can be tilted to different angles for bevel sanding.

Spindle sanders are commonly used in woodworking for sanding curved and irregularly shaped surfaces, such as chair legs, table legs, and other furniture components. They can also be used for sanding and shaping other materials, such as plastics, composites, and even metal.

Safety precautions should be taken when using a spindle sander, including wearing eye and ear protection, using a dust collection system, and avoiding loose clothing or jewelry that can get caught in the machine. When used properly, a spindle sander can help users achieve smooth, even surfaces and precise shapes in their projects.

Wood Lathe

A wood lathe is a woodworking machine that is used to shape and turn wooden objects, such as bowls, spindles, and furniture components. It consists of a motorized spindle that rotates a workpiece at high speed while a cutting tool is held against it to remove material. The lathe has various components, including the headstock, tailstock, tool rest, and bed.

The headstock of a wood lathe houses the motor and the spindle, which holds the workpiece in place. The tailstock supports the other end of the workpiece and can be moved to adjust the length of the workpiece. The tool rest is an adjustable support that holds the cutting tool in place at the correct angle and height for shaping the workpiece. The bed is the main framework of the lathe that supports all of its components.

To use a wood lathe, the workpiece is secured between the headstock and tailstock and is rotated at high speed. The cutting tool is held against the workpiece using the tool rest and is moved along the surface to shape it. The lathe can be adjusted to different speeds and can be used for a variety of cuts, including facing, turning, drilling, and sanding.

Safety precautions should be taken when using a wood lathe, including wearing eye and ear protection, using a dust collection system, and avoiding loose clothing or jewelry that can get caught in the machine. The cutting tool should be kept sharp and properly secured in the tool rest, and the workpiece should be securely mounted and balanced to prevent it from vibrating or coming loose during operation.

In addition to woodworking, wood lathes are also used in metalworking and pottery. With proper use and safety precautions, a wood lathe can help users achieve precise and intricate shapes in their projects.

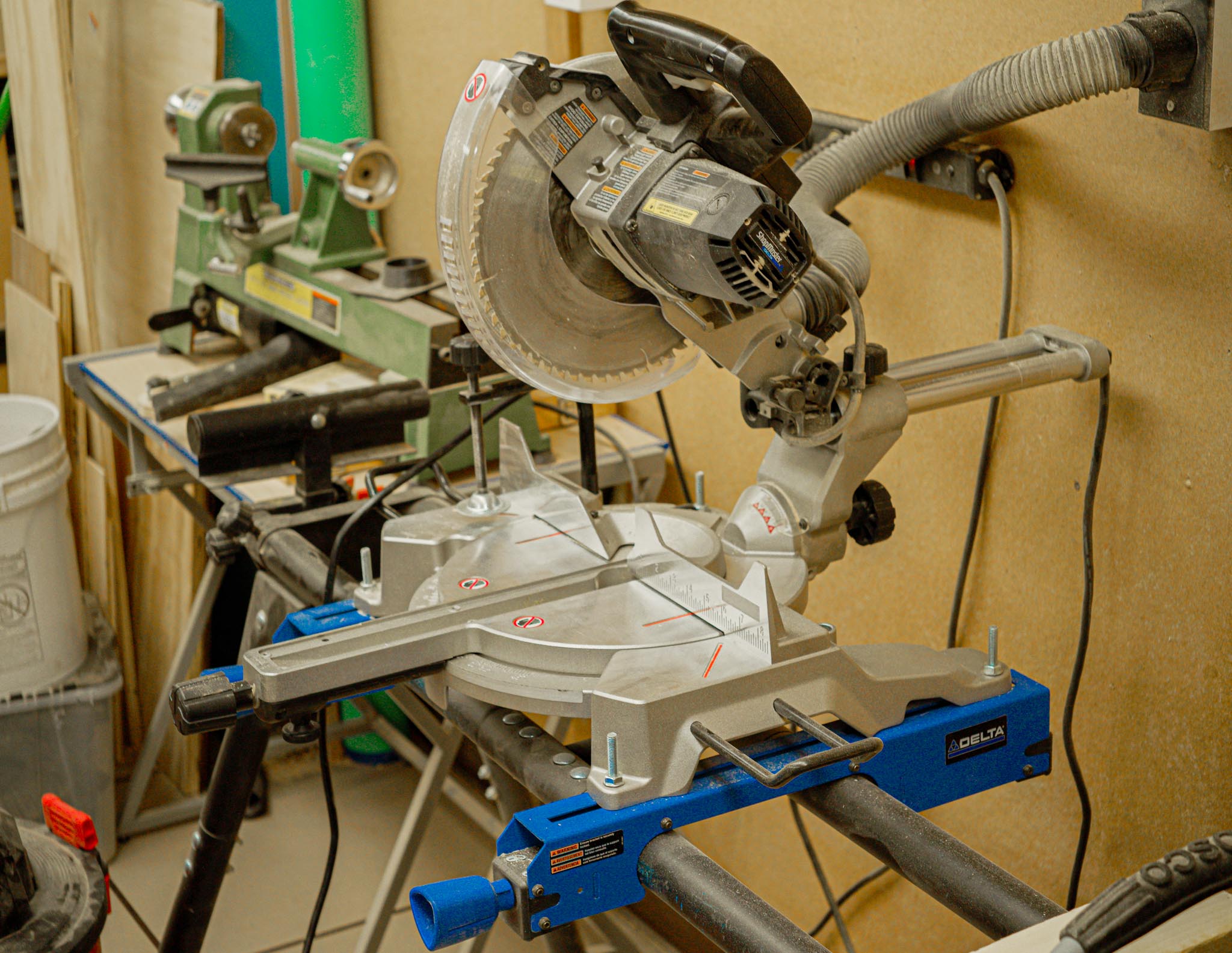

Miter saw

A mitre saw, also known as a chop saw or a miter box, is a power tool used for making precise and angled cuts in wood, metal, and other materials. It consists of a circular saw blade mounted on a pivoting arm that can be angled and lowered to cut through the workpiece.

The saw blade of a mitre saw is typically between 8 and 12 inches in diameter and has teeth that are designed to cut through the material being worked on. The pivoting arm can be angled to make mitre cuts at different angles, typically ranging from 0 to 45 degrees. The machine also has a fence or guide that can be adjusted to help keep the workpiece in place and ensure accuracy.

To use a mitre saw, the material being cut is placed on the saw table and secured against the fence or guide. The saw blade is then lowered onto the material and the pivoting arm is angled to the desired angle for the cut. The saw is then turned on and the blade is lowered to make the cut. The machine’s adjustable depth stop can be used to control the depth of the cut and ensure consistency.

Mitre saws are commonly used in woodworking and construction for cutting trim, moulding, and other materials at precise angles. They are also used in metalworking for cutting metal pipes and other materials. With the right blade, they can be used on a variety of materials, including plastics and composites.

Safety precautions should be taken when using a mitre saw, including wearing eye and ear protection, using a dust collection system, and avoiding loose clothing or jewelry that can get caught in the machine. When used properly, a mitre saw can help users achieve precise, clean cuts in their projects.